|

|

||

|

Residual concrete floors, new slab on grade pours and suspended floors can surprise any polishing contractor with the flatness vs the levelness. Appealing to the eye but problematic to the polisher.

Over the years we have come across new slab on grade, restorations of homes and repours of basements, commercial floors with a variant of concrete placement techniques such as concrete pump trucks to wheel barrow placement and including hand mixed in confined or difficult areas to get the product to where is has to be.

Once poured, leveling tools such as wood, magnesium aluminum screeds, bull floats, hand and or power trowels, leveling tripods all leave a history behind sometimes not noticeable at the time of completion. Afterall, the floor is still wet and sometimes difficult to backtrack to certain areas for fine corrections.

The polisher comes in and begins his grind with aspirations of achieving the clients finished appearance. Perhaps with an aggressive 30 Grit diamond working to expose as much aggregate for his client as possible. Followed with 50 grit, 80, 150, and moving along to honing with resin pads to increase the gloss appearance.

Our challenge is then revealed: Saw cuts will shrink and contract upwards from the surface exposing and area of higher degree of curl or lift that will grind the first and the heaviest and exposing the most aggregate.

This condition can be a challenge to the contractor especially if the specs are calling out a min exposure of aggregate. This can be cream up to salt and pepper condition. Starting with a less aggressive diamond in the first cut will reduce the exposure but still leaving a similar result because of the higher curl or shrinkage in the saw cut areas.

This drawing is illustration of flatness (A) below vs level (B) . (A) flatness condition will grind a more consistent level but will still be dependent on the aggregate exposure to gravity or placement of the stone for a homogeneous appearance. (B) however, creates waves of aggregate inconsistently dispersed in the matrix of the concrete.

Polished concrete is a beautiful alternative to other flooring options. Polished Concrete can be cost affective and a perfect option for in floor heated floors, additions and new builds. The client’s expectations can be and should be discuss in length with your polished contractor. It is vital to remember the polisher does not pour the concrete or place the aggregate especially on old heritage floors.

The beauty of Polished concrete is the natural and random appearance it can offer. Low maintenance and easy to clean for many years of enjoyment.

Should you have questions or concerns about your next polishing project, feel free to call me at Garage Enhancements Ltd. 519-220-9714 or email me at [email protected]

|

||

|

||

|

||

|

|

|

|||

|

Consumers, architects, contractors, building landlords, maintenance people and many other professional groups over the years have been drawn to the finish, versatility and long-term cost saving of beautiful polished concrete.

Situation: We have a beautiful custom-built home with in floor heat throughout. The builder, architects, and designers are looking for a beautifully finished floor, low maintenance, excellent heat transfer to the surface of the concrete at a competitive and reasonable price.

Problem: Not all the surface areas are being used for the same condition of living. We may have the main floor, family rooms, kitchen, bathrooms, utility, bedrooms, storage, workshop, mudroom and perhaps a playroom. Are they all used with the same environment and condition? Grease in the kitchen? Urine in the washrooms, sump pumps in the utility rooms, salt in the mudroom and with paints in the workrooms.

Implication: The wear and tear on each area will be different depending on traffic and uses. Urine in the polished washroom floor is a disaster waiting to happen beside toilets and standing urinals. The acidity from the urine splash will decay through the densifier and the concrete itself over time. Grease from cooking with permanently stain polished and densified concrete and salt spillage from your water softener will also damage your polish in the utility room. Stained and colored floors added to the polish process will also suffer the same negative effect if subject to the above environment.

Need: Communication from the designers, general contractors, architects, and your polish contractor must be profusely honest on the reality of what to expect over the years of use in each room. Some areas will and need to be recommended for additional protection of a sealer to avoid stain penetration and acidic erosion.

Clear Coatings to protect these vulnerable areas of Polished Concrete.

Protecting polished concrete is achieved in two ways.

Ground and coated surface with a polyaspartic chemical resistant clear coat will resist urine acidity oven grease, salts, red wines, and other intrusive household chemicals and foods.

True polished concrete with a smooth slip resistant option offers an excellent heat transfer for in floor heating elements. Excellent wear and easy to maintain with a weekly/monthly maintenance process to keep its beauty.

With a little maintenance, both finishes your floor will last for many years of enjoyment and comfort.

Be aware of what you're getting and never be afraid to ask questions. We have been in business for 13 years and built relationships through outstanding quality and remarkable service.

Lawrence Clark

Garage Enhancements Ltd

Known for Superior Quality.

|

|||

|

|||

|

|||

|

|||

|

|

|

|||

|

Discovered in the early 1930’s epoxy has been developed continually to meet new challenges for the ever-changing world we live in.

From higher strengths to more malleable internals to waterproofing and heat retention the development is ongoing. Luckily for the average garage epoxy requirement our selections are much more narrowed and defined based on our requirements.

Often over the year, we receive requests for an estimate through our website. Some requests offer all the pertinent info on the customer's requirements such as who, what, where and when followed with a contact number and perhaps a few special requests or good consumer questions.

Others ask for just a price and offer only a return email. This is very difficult to give a reliable price per square foot. Garage applications can be done with a few different types of epoxy ranging from the popular home improvement stores that offer more residential material lending to a do it yourself version for easy installation. To a commercial grade epoxy creating a more substantial build in thickness and much higher wear properties. Commercial epoxy can be water based, part solids from 70% up to a 100 % solid epoxy leaving the latter epoxy giving the thickest layers possible with a single roll down the application.

Do I get a primer that is part of the installation? This is the most important part of any installation for the epoxy product. Most premature features are caused by delamination (peeling) off the substrate (concrete floor). These are caused by moisture intrusion, poor saturation of the epoxy material, dirt, grease, and several other contaminants not removed from the concrete floor before installment.

Is your epoxy physical properties the same as your competitors? This can be the unknown, especially when asking strictly for a generic square footage price. Epoxies can have various properties all beneficial to the task at hand. And now the newest one-day install is Polyaspartic coatings. These products are introduced to the concrete industry for the main reason of quick drying back into service and UV sunlight stability. The one-day process is still a concern when looking at soaking times into the properly prepared concrete floor. If a Polyasparitic solid product is used as a primer, it dries quickly and shortens the soaking penetrating time into the concrete. Depth of saturation is very important for the delamination and pull strength of your coating.

What is your thickness requirement? These are pertinent questions to be asked on any estimate as thickness translates to wear. Not bond, BUT friction and compressive wear. Thickness is also the red flag when a consumer is browsing for the price. Coating films can be functional from 3mils up to 30mils and much more. If your walking once a week on a floor, do you need the same product thickness as you would when driving your car in and out several times daily with tires full of winter conditions? (salt and sand). How about forklift traffic and carrying heavy duty loads over your floor 24 hours a day? Therefore, you need to be a little more forth giving with your information when filling out any quote request. Reputable coating companies know coatings and can help you determine what you require, perhaps not the cheapest…. BUT what you need for your application.

There are many more unknowns to your application, and these are just a few that you need to be answered before you make the final decision on your selected contractor.

In closing, ask away. Garage Enhancements Ltd has been around for well over a decade installing residential, industrial, medical and food grade floors in south Western Ontario.

“Know what you're paying for and get what you need!”

Lawrence Clark 519-220-0714 President of Garage Enhancements.

|

|||

|

|||

|

|||

|

|||

|

|

|

|||

|

Stamped concrete can sometimes fail for a variety of reasons. Nevertheless, it ruins the look of the entire patio, driveway or walkways.

Limited options are available for a new and durable surface.

Grinding the surface smooth and polishing up to a 400 diamond finish is a beautiful limited maintenance remedy. Choosing a densifer, urethane or a polyaspartic top coat, the concrete will be revitalized for many more years of use.

For further information call us at Garage Enhancements Ltd 1-519-220-9714 or click here to contact us

|

|||

|

|||

|

|||

|

|||

|

|

|

||

|

Garage Enhancements Ltd was hired to put some much needed tender care to this 40 year old swimming pool walkway and try and bring it back to life.

Our client was very open to new ideas that would fill a lot of pitting and scaling from years of wear, heavy power washing and natural concrete decay over time.

Garage Enhancements installed an overlayment product from Elite-Crete products with a simple trowel finish for anti slip results.

You would never guess this pool top is 40 years old after we completed the transformation ..

|

||

|

||

|

||

|

|

|

|||

|

Garage Enhancements Ltd. was specified to transform an old LCBO in Oakville, Ontario into a New York style loft to be used as a high end showroom.

The floor was covered in tile and carpet glue, riddled with holes cracks and crumbling in areas.

Garage Enhancements was more than happy to take this seemingly impossible challenge .

After days of grinding starting with a 40 grit diamond cutter progressing up to a 1500 resin, several bags of patching material and some tremendous efforts from great employees we could see the brilliant results start shining through .

“Polished Concrete , simply a brilliant alternative “. Let Garage Enhancements Ltd show you how. Contact us today.

Have a look at the before and after shots.

BEFORE

AFTER

|

|||

|

|||

|

|||

|

|||

|

|

|

||

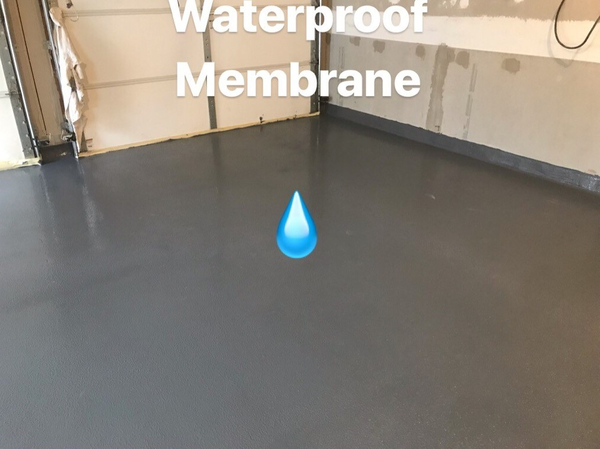

“Buyer Beware"

Garage Enhancements received a call a few weeks ago from a customer suffering from buyer remorse.

Our Client bought there first house in Waterloo (30 year old home) and got a surprise they weren’t planning on .

After a day of heavy snow fall. The customer pulled into there garage to keep the car protected from the harsh winter elements. Waking the next morning they discovered the snow melt from the car in the garage didn’t stay in the garage!

The ceiling in their finished basement was saturated and the melted salt water seeped through the concrete floor in the garage ruining the hardwood basement floor. Garage Enhancements corrected this unfortunate situation with a waterproof membrane system from BASF.

After grinding, filling the cracks and installing radius coves around the full garage, a two coat system was installed.

No more leaks for the NOW happy customer.

|

||

|

||

|

||

|

|

|

Garage Enhancements Team 4 June 20, 2019 |